Vertical packaging machine

Friday July-18 2025 17:41:05

What is Vertical packaging machine?

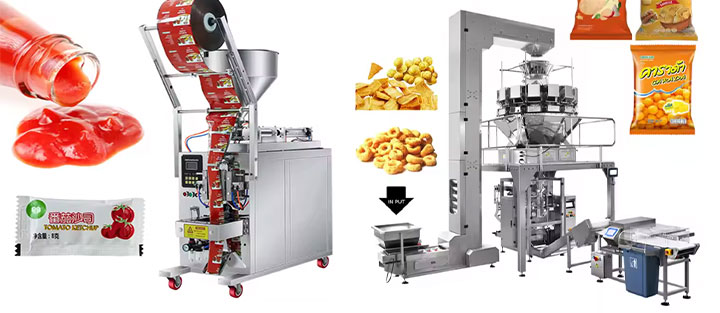

Vertical packaging machine is a packaging equipment that automatically completes the weighing, bag making, filling, sealing and other processes of bulk, granular, powder or liquid materials. Its structure design is compact and occupies a small area. It is suitable for automated packaging in multiple industries such as grain, food, chemical, and pharmaceutical. Through film rolling into bags, Vertical packaging machine greatly improves packaging efficiency and packaging consistency, and is widely used in the mass production of small and medium-sized bag products.

The working process of Vertical packaging machine is that the material enters the former through the feeding device and is rolled into a cylinder; the longitudinal sealing device seals the film longitudinally. Then the transverse sealing device seals and cuts horizontally according to the set length to form an independent packaging bag, and completes the filling of granules, powders or liquids at the same time.

Other common types of Vertical packaging machine

Vertical packaging equipment mainly includes three categories: vertical filling and sealing packaging machine integrates filling and sealing, which is suitable for powder and granular materials; vertical forming filling and sealing packaging machine (VFFS machine) realizes fully automatic bag making, filling, sealing and cutting, and has strong versatility; vertical film sealing machine specializes in plastic film heat sealing, which is economical and practical. Vertical Form Fill Seal Packaging Machine: This type integrates filling and sealing, and is suitable for materials such as powders and granules. It is widely used in seasoning, milk powder, feed and other industries. It can be linked with a weighing device to achieve high-precision metering (the error is usually controlled within ±1%), and stainless steel contact parts are used to ensure hygiene. The typical model can process 30-60 bags/minute (depending on the specific function).

Vertical Form Fill Seal Packaging Machine (VFFS Machine): This model can automatically complete film roll bagging, metering filling, and heat sealing and cutting. The equipment has flexible bag making specifications (adjustable width 50-400mm), suitable for pillow type/four-side seal/self-supporting bag and other bag types. High-end models are equipped with photoelectric tracking and gravity sensors, and the packaging speed can reach up to 120 bags/minute, which is particularly suitable for the GMP standard requirements of the food and pharmaceutical industries. Vertical film sealing machine: Focusing on economical solutions, it uses constant temperature ceramic heating strips or aluminum alloy sealing knives, suitable for sealing PE/PP bags with a thickness of 20-200μm. The workbench height is usually adjustable (range 500-900mm), and the maximum sealing length is 400mm. The basic model has a power of about 600W, which is suitable for small workshops with a daily output of less than 2,000 bags. Some models support foot switch control to adapt to semi-automatic production lines.

What are the advantages of Vertical packaging machine?

Vertical packaging machine is suitable for a variety of materials such as granules, powders, liquids, sauces, such as snacks, condiments, daily chemical products, etc., with strong adaptability; it adopts automated continuous operation, fast packaging speed, and the output of a single machine can reach 30-100 bags/minute, which is suitable for medium and large-scale production needs; the vertical design occupies a small area and saves space, while integrating bag making, metering, filling, sealing and other functions, and is easy to operate; equipped with high-precision metering devices (such as screws, measuring cups or electronic scales) to ensure that the weight of each bag is consistent and reduce errors; the packaging size and parameters can be adjusted to adapt to products of different specifications, and some models support multiple sealing methods such as back sealing and three-side sealing; the structure is sturdy, the operation is stable, the failure rate is low, it is suitable for long-term continuous production, and the maintenance cost is low.

What are the technical parameters of the Vertical packaging machine?

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Vertical packaging machine case

Vertical packaging machine is used in high-speed packaging scenarios in food, medicine, chemical and other industries. For example, in the snack industry, a potato chip manufacturer uses a fully automatic Vertical packaging machine to achieve high-speed packaging of 120 bags per minute, accurately completes the metering, bag making, filling, sealing and coding processes, greatly improves efficiency and reduces labor costs. In the field of daily chemicals, a washing powder manufacturer uses a vertical packaging machine to achieve automatic switching packaging of various specifications (500g-5kg), with strong sealing and excellent moisture-proof effect. In addition, pharmaceutical companies use this equipment to complete aseptic packaging of granules, which meets GMP standards and ensures product hygiene and safety.

What is the difference between a Vertical packaging machine and a horizontal packaging machine?

The main difference between a Vertical packaging machine and a horizontal packaging machine lies in the material type, structural form and application direction. Vertical packaging machines are generally used for easy-flowing materials such as liquids, powders, and granules, which are convenient for gravity feeding and easy to operate; their sealing forms are mostly vertical sealing + horizontal sealing, which is suitable for vertical bag packaging. Horizontal packaging machines are mostly used for the packaging of solid items or more regular products, suitable for the heat sealing process of the bag has been formed, and are commonly used in the packaging of candy, bread, and instrument products.

In addition, the vertical structure saves more space and is suitable for centralized operation of the workshop assembly line; the horizontal structure facilitates lateral conveying and directional arrangement of products, and is suitable for high-speed packaging operations.

Vertical packaging machine has become an indispensable packaging equipment in modern production lines with its advantages of high degree of automation, fast packaging speed and wide application range. Through reasonable selection and supporting system configuration, the packaging efficiency and finished product quality can be greatly improved. In view of the different material characteristics such as powder, granules, liquids, and various bag types such as back sealing, three-side sealing, and four-side sealing, users can choose the corresponding machine model and sealing method (such as heat sealing, ultrasonic sealing) according to the production capacity (20-120 bags/minute). In addition, the modular design makes the equipment easy to clean and maintain, and can quickly switch packaging specifications, providing flexible and stable intelligent packaging solutions for food, medicine, chemical and other industries, significantly reducing labor costs and improving product market competitiveness.